One of the most important and basic mechanical devices, the screw is used very frequently in our day-to-day life. Right from making toys to assembling vehicular parts, this simple machine is the best fixing medium regarding different materials. Read this ScienceStruck post for more information about this topic.

Fast Fact

In 1967, one of the largest screws or bolts was manufactured in Scotland by the Penrith Engineering Works. The length and diameter of these machines was about 24 feet and 4 feet, respectively. These screws were made from a very strong element called iridium, and oil tankers were connected to each other using such devices.

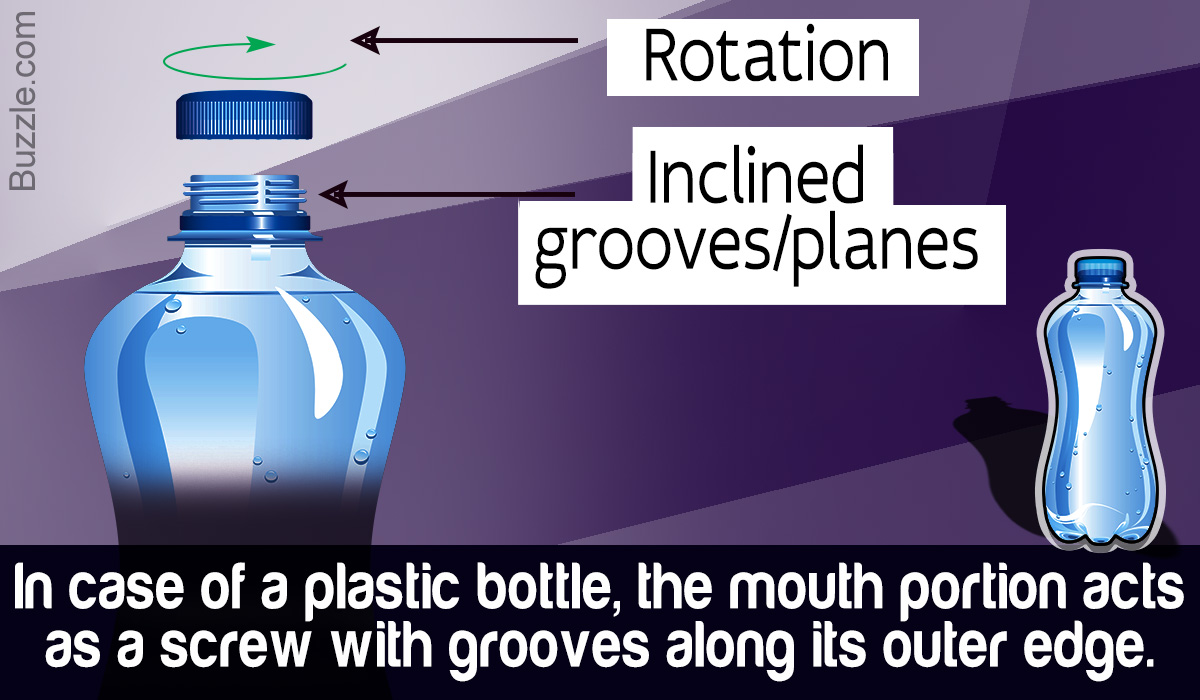

A screw is one of the six simple machines, with the other five being the lever, wheel and axle, pulley, inclined plane, and wedge. It is one of the most commonly used devices in the world. The screw has an appearance of a thin metal stick with a turning head on top and grooves along its length. Conventionally, it is defined as a mechanical device that has helical-inclined planes and is capable of converting torque to linear force and vice versa.

The inclined planes that form the threads are wound entirely along the screw shaft, and hence, it becomes easier to fix different objects, as driving it down in a rotational form requires less effort than pushing a nail by application of effort in a vertical direction. Also, nails have the tendency of bending when they are used, whereas a screw would never bend as force is evenly spread along the entire shaft. These are a few reasons why using a screw is preferred over a nail, and why the latter is being phased out slowly.

History

The initial design used was the Archimedes screw, which was developed from Archimedes himself. It was mainly utilized to draw out water from wells, rivers, lakes, etc. This screw had a longer length between its threading and was operated manually. Prominent uses of this device were seen when water was drawn up to the Hanging Gardens of Babylon. The same design was also utilized in the Mediterranean regions for many centuries for irrigation processes, and also to facilitate oil and wine presses. The Archimedes Screw is used even today in numerous mechanical operations. It has a wide application in the form of conveyor screw devices, especially used in the food processing industry.

Innovation of the modern screw that is used primarily as a fastener is associated with the development of the lathe machine. In the period before modern devices were mass-produced, cotter pins and pin bolts were widely used as fasteners. Actual development of the modern screw began after Jesse Ramsden, a British instrument manufacturer, perfected a device called ‘screw-cutting lathe’ in the 1700s. This lathe was further improved and patented in 1798 by David Wilkinson. In the following decades, the importance of threaded fasteners and screws greatly increased in mechanics, which led to the ‘standardization of thread forms’. The process of standardization is still ongoing, and has also led to the development of ISO metric screw threads and the Unified Thread Standard. The ‘turret lathe’ and ‘screw machine’, which were developed in the 1840s and 1870s, respectively, boosted the mass production of screws. Some important types of such devices that were developed in the course of evolution of modern designs were the Robertson Screw (developed by P. L. Robertson in 1908), and Hex Socket and Phillips-head Screw (developed by Henry F. Phillips).

Working Principle and Explanation

The helical-inclined planes present on the screw are referred to as threads or threading. The structure, space, size, and material of which the screw is made up of determines its strength. This strength is also referred to as the mechanical advantage. The turning head of the screw is a provision or facility where the force from a screwdriver can be applied, and torque can be generated. When force is applied on the screw head, it is transferred to the screw threads, which further begin to advance in the downward direction. The exact opposite motion occurs when one starts removing a screw from the material it is fixed to.

The distance covered by a screw in a straight line in one single rotation is called the lead, while the measurement between two successive inclined planes is called the pitch. The Mechanical Advantage (MA) of this simple machine is controlled by the degree of the lead; less distance covered means more MA, and vice versa. Depending on the orientation of the screws, they are distinguished in two types: right-handed (the helical threads move in a clockwise manner) and left-handed (the threads move in an anti-clockwise manner). The former are most commonly used for numerous application, while the latter are used only for specific purposes (for example, a left-side bicycle pedal and few types of light bulbs). If the pitch is less, greater force is applied by the screw onto the material, in which it is inserted. Also, if the incline of the threads increases, the input force also increases.

The ratio of the screw circumference to the distance covered by it at the time of every rotation is called the Ideal Mechanical Advantage (IMA). This ratio is represented as:

IMA = Screw Head Circumference/Distance Covered by the Screw Shaft

If circumference of the head is 2πƖ, where Ɩ is the radius of the head surface, and Ƥ is the distance advanced by the screw on one rotation, the IMA can be represented as:

IMA = 2πƖ/Ƥ

The Actual Mechanical Advantage (AMA) is the ratio of the force applied during turning of the screw head to the force exerted by the device on the material, in which it is to be inserted. Thus, this type of mechanical advantage can be represented as:

AMA = Input Force/Output Force

One amazing advantage of the screw over the nail is that it can get automatically locked in the material, where it is inserted. This is caused due to the extra friction produced by the inclined planes, when it rotates and gets fixed in the interior portion.

The following pictures illustrate the various types of screws that are used currently.

Applications in Modern Era

Though the latest designs were developed in a very short period of time, the ability of screws to transfer torque has made it a very effective tool. It has also replaced rivets and fastening pins in the mechanical industry due to its ease of operation and utility. This type of simple machine is used in machinery, where power is transferred from one part to another.

A very good application of this device is regarding micrometer gauges, which are used in mathematics and physics for precise measurement. Conveyor belts, propellers, drillers, helicopter blades, etc., are a few prominent examples, where the use of screws can be seen in our everyday lives. The concept of screws is also used in an architectural sense, like building spiral staircases; the motion of a person climbing them is same as that of a normal screw.

This simple machine can handle about five times the holding strength, as compared to the same strength of a nail. The screw is still undergoing many changes and is evolving continuously. Due to its basic principle of physics, it is considered a member of the six simple machines, and has become an indispensable part of modern mechanics.