Brass, an alloy made from zinc and copper is well-known for its durability and elasticity. Here’s more about the composition, characteristics, and applications of this alloy.

Did You Know?

In prehistoric era long before zinc was discovered, brass was prepared by combining copper and calamine (an ore of zinc).

When a metallic or non-metallic element is combined with a metal, an alloy is formed. Mixing of two elements to form a different compound can yield an alloy with most desirable properties. Mixing zinc and copper in a solid solution yields brass which is widely used for a variety of purposes.

An object can be called solid brass if it is made of pure brass material, it need not necessarily be of a solid shape. And those that are plated with a thin film of brass are called plated. It is difficult to clean and maintain plated brass artifacts while, the solid ones can be cleaned thoroughly.

What is Brass Made of?

Being yellow colored and made from zinc and copper, this alloy has an appearance like gold. Normally its composition is made up of 33% of zinc and 67% of copper. It is also called ‘Yellow Brass’. Color of brass ranges from color of pure copper to yellow to white depending on the amount of zinc and copper.

Types of Brass

Brass can be subdivided into different classes, depending on the quantities of copper and zinc. The ratio of mixture determines various properties of the alloy such as the melting point, malleability, ductility, resistance to corrosion, etc.

Alpha brass: <35% zinc and >65% copper

Alpha-beta brass/Duplex brass: 35-35% zinc and 55-65% copper

Beta brass: 45-50% zinc and 50-55% copper

White brass: >50% zinc and <50% copper

As the proportion of zinc in the alloy increases, the alloy loses its malleability and becomes brittle. Malleable varieties of brass can be worked upon, even when cold. As the brittleness increases, it becomes mandatory to heat the brasses before working upon them.

Properties of Brass

▶ Color of brass alloy depends on the proportion of its constituent metals, zinc and copper.

▶ The density of brass is about 0.303 lb/cubic inch. It can also be expressed as 8.4-8.73 grams per centimeter3.

▶ Copper has bactericidal properties, which are inherited by brass too.

▶ Brass doesn’t possess magnetic properties hence, is non-ferromagnetic.

▶ Brass offers low friction and has low melting point of about 900 – 940 o C.

▶ Most of the varieties of brass are recyclable.

▶ Brass is resistant to corrosion or tarnishing.

▶ Brass alloys containing more than 45% zinc cannot be worked upon when cold.

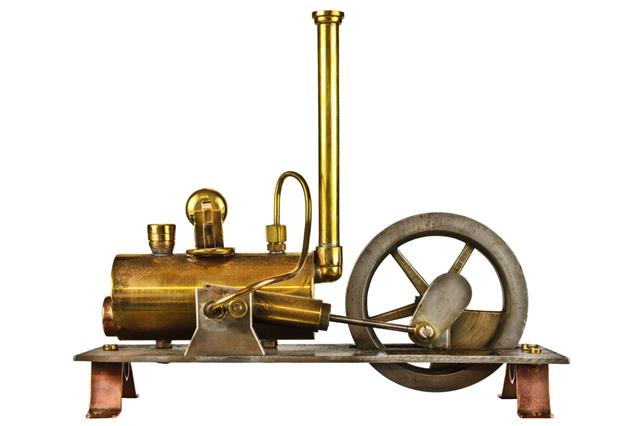

Applications of Brass

▶ Brass being gold-colored is widely used in decorative fixtures and candle holders.

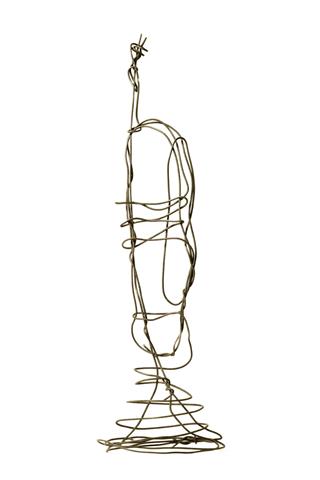

▶ Brass is used in a number of musical instruments such as flugelhorn, horns, trumpets, baritone, bugles, tuba, cornet to name a few.

▶ Brass is used in zippers on clothes and bags.

▶ Valves made of brass are soldered to copper plumbings.

▶ Having high degree of malleability, brass can be hammered into desired shapes.

▶ Since it offers less friction, it is used to make door knobs, locks, handles etc.

▶ Brass is used in fireplace equipment.

▶ Dezincification is the process of removing zinc from the brass. DZR brass is highly resistant to corrosion and hence used in areas prone to corrosion such as boilers. It consists of minute quantity of arsenic.

▶ Astronomy telescopes consist of a brass covering.

▶ Two varieties of brass: cartridge and gliding metal brass are widely used for making ammunitions such as bulletproof jackets.

▶ It is used in making currency coins.

▶ Brass finds its applications in navigation and surveying instruments.

▶ Aluminum brass containing around 2% aluminum, is used in condenser tubes and heat exchanger devices.

▶ Boiling point of brass is lower than that of zinc or copper.

▶ Malleability of brass is higher than its parent elements.

▶ Brass has more strength than zinc or copper. Copper hardens on addition of zinc.

Minute quantities of lead is added to make the brass alloy fit for machining. The low melting point as well as the flow capacity of brass makes it perfect for making casts. Its other properties can be changed as per requirement, simply by varying the ratio in which the parent elements combine.