A wedge is a type of inclined plane, which is mainly used to cut an object into two pieces, or separate out portions of an object by applying some force to it. Wedges are a part of our everyday lives, and they are used in a myriad ways in activities like eating, carving, building machines, etc.

Did You Know?

The wedge is probably the first simple machine to ever be used, and relevant evidences are present in the form of crude hand axes and arrow heads made during the Stone Age. Prehistoric man mainly used them for hunting purposes.

The kinds of devices that are characterized by simple working mechanisms, which make it easier for us to accomplish various tasks, are called simple machines. The direction as well as the magnitude of applied forces can be changed with the help of such devices. Thus, the force applied is used to move, lift, and even fix an object or a load, in the form of work. A few of our body parts also function as simple machines; for example, our teeth work as wedges, and separate out the food particles while eating.

In many cases, some combinations of simple machines are used to perform the work in a more efficient manner. For example, when a person strikes a wooden block with an ax, the blade acts like a wedge, whereas, our arm acts like a lever. There are six basic types of these machines:

- Wedge

- Wheel and Axle

- Screw

- Lever

- Pulley

- Inclined Plane

The following paragraphs explain the working mechanism of a wedge, along with its examples and applications.

Explanation

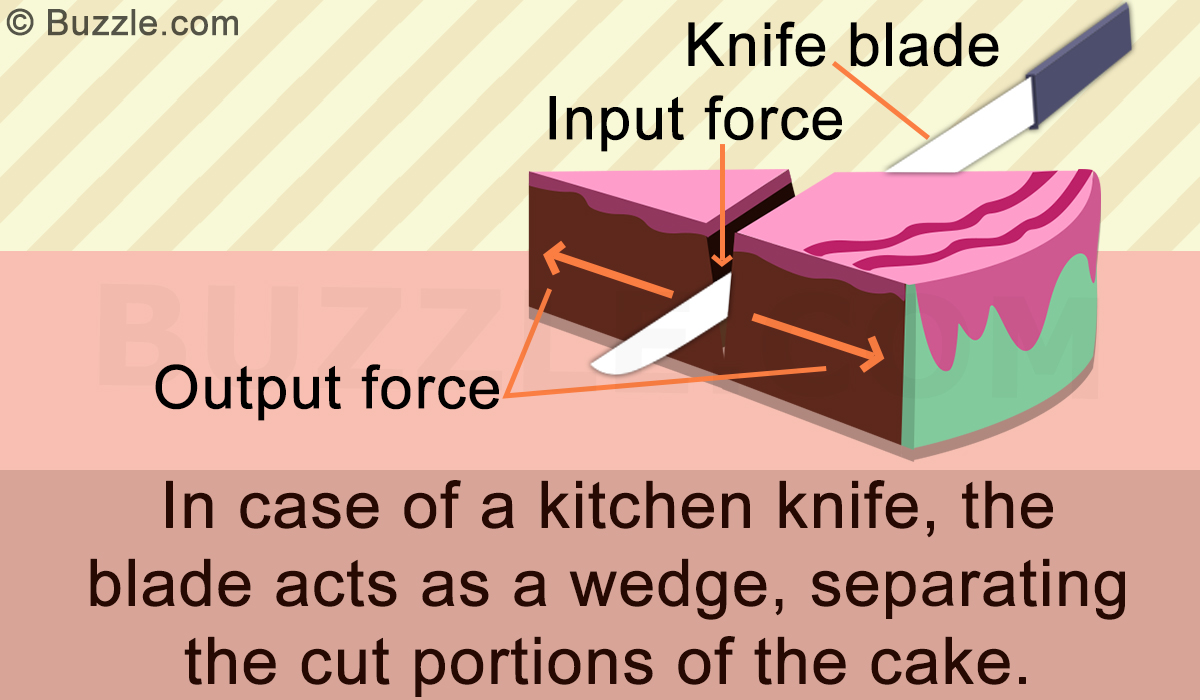

A wedge can be simply described as a type of inclined plane, with either one or both surfaces inclined. One end is blunt while the other end is sharp. When a force is applied on one end, it gets divided into output forces that are exerted in opposite directions, perpendicular to the input force. The work done depends on the input force magnitude, as well as the length of the inclined side and width of the wedge.

The first substantial use of this simple machine is controversial; evidences suggest that many wedge-like objects were utilized in ancient Egypt to build structures like the Pyramids and Sphinx. Apart from rocks and stones, animal horns and antlers, tree branches, and sharpened metal were also used for several purposes. Over time, other types of wedges, like blades, swords, chisels, nails, scissors, door stoppers, etc., were developed and used.

Working Principle

When a force is applied on the broad end of a wedge after placing it on another object, it travels down towards the sharp side and gets divided into the output forces. Thus, the target material is split into two parts, and the wedge can be said to be an anchoring material that fastens itself inside the object. Let’s say that the input force is Fi, and the corresponding wedge velocity is Ci. Now, as the force reaches the device point, the output force is termed as FO, along with a velocity of CO. Hypothetically speaking, if no external force like friction has any effect on this process, then the input force will always be equal to the output force. Thus, the power that is involved in cutting the object is represented as:

P = Fi × Ci = Fo × Co

As other forces are absent, the ratio of the forces is equal to the ratio of their velocities:

Fo ÷ Fi = Ci ÷ Co

As both the velocities are perpendicular to each other, they can be said to be constant for specific force ratios. Hence, the output velocity can be written as:

Co = Ci × tanϴ

where ‘ϴ (theta)’ is the wedge angle, along which the force is applied.

The force ratio that refers to the mechanical advantage is given below:

Fo ÷ Fi (MA) = 1 ÷ tanϴ

This is called the mechanical advantage (MA) of the wedge, and it mainly denotes the amount of effort needed to perform the work.

The Ideal Mechanical Advantage (IMA) is represented as the ratio of the wedge length to the wedge width, and is illustrated in the image given below:

IMA = Wl ÷ Wb

Here, Wl is the length of the wedge from the sharp surface to the blunt portion, and Wb is the breadth or width of the device across the blunt surface. The IMA is calculated when additional external forces like friction are also present. The length can also be called the penetration depth, which indicates how deep the device can go inside an object.

The effort required to split or lift an object using the wedge is inversely proportional to the length, and directly proportional to its width.

Applications and Examples

As seen in the illustration below, the ax distributes the output force that is parallel to the length of the wood block and perpendicular to the input force. In case of the shovel, the output forces are divided towards the back and front of the shovel surfaces so that the mud can be separated easily. In the third example, the chisel is used as a wedge to carve a wooden block, and a hammer is used to provide the input force. The output is in the form of forces that are oriented along the block surface.

A wedge is extremely useful to hold, cut, separate, fix, and lift various kinds of objects. In today’s world, with the help of modern technology, different varieties of this machine have evolved, like electric saws and drillers, which also can be said to be used as wedges. These devices can also be coupled with other machines for increasing the efficiency of work.