A hydraulic motor works by channelizing the power generated by fluids and converting it into motion. Let us understand how a hydraulic motor works through this write-up.

A hydraulic motor makes use of fluids in its working and employs the science of hydraulics. It allows the conversion of pressure resulting from fluids (liquids and gases) into forces like angular displacement and torque. Basically a rotatory part of hydraulic machines, the hydraulic motor works in association with the hydraulic cylinder. There are many different types of hydraulic motors. Hydraulics being an advanced science, many applications of these motors have been developed. Useful details pertaining to working of this motor, types and applications can be found below.

Hydraulic Motor Working

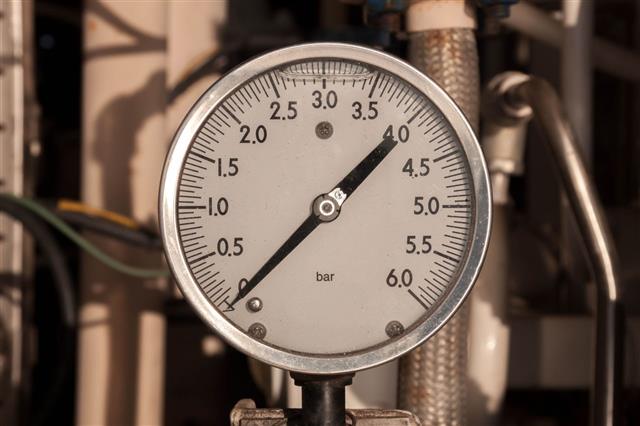

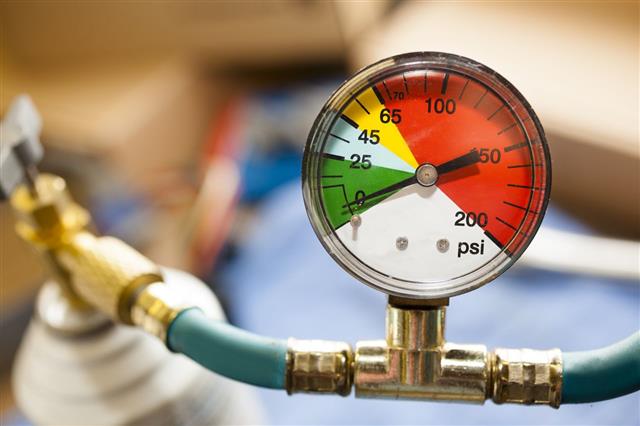

The hydraulic motor receives a fluid that is channeled into pressurized tubes by the hydraulic pump. The fluid is originally stored in a reservoir. Process of internal combustion helps the hydraulic pump drive this fluid into tubes which is further carried to the hydraulic motor. The fluid which flows in a pressurized form turns the motor as it flows through it. This fluid, after flowing through the motor comes back to the reservoir. The cycle repeats in order to keep the motor running.

Hydraulic Pump

The hydraulic pump which is used to drive the fluid has many different forms. Gear pump is the simplest form of hydraulic pump. In gear pumps, a case acts as an enclosure for two meshed gears. Rotatory action of these gears pushes the oil from inlet to outlet. The rotatory vane pump is another type of hydraulic pump. In this form of hydraulic pump, the oil is pushed with the help of a rotating beam, which further passes through a screw pump.

Hydraulic Cylinder

In few hydraulic machines, hydraulic cylinder is used for creating motion. Pressure is created by the cylinder when oil is pushed into it. This pressure is exerted on a piston and it slides out. Such pistons are connected to an assembly of various devices including different types of levers. The different types of construction vehicles make use of pistons like these to create motion.

Working of Different Hydraulic Motors

Axial plunger Motors

It is a motor which makes use of hydraulic cylinder for generating motion. Since the piston of this motor is attached to a rotatory axle, the motor is also referred to as the rotating piston motor. The hydraulic pressure pushes the piston and help in turning the rotor. When the piston is completely released or pushed out, the oil is discharged; this discharge of oil enables the motor to turn around.

Radial Piston Motors

These motors are available in two types, namely the crankshaft type and the multi-lobe cam ring type. A crankshaft motor possesses a single cam piston that is pushed inwards. The motor is marked by high starting torque characteristics. A multi-lobe cam ring motor possesses multiple lobes and a piston which moves in an outward manner in a direction opposite to the cam rings. This motor has the capability to generate high amount of power. It runs smoothly if installed in low-speed applications. The motor is characterized by a high starting torque; it is capable of producing a smooth output.

Vane Motor

A vane motor is capable of producing rotating motion in either clockwise or counterclockwise direction. The parts of vane motor include a drive shaft, slotted rotor, rectangular vanes fitted in slots on rotors and other parts which hold together this assembly. The vanes freely slide in and out of the rotor while the latter moves in a circular motion. Compressed air is forced into the assembly through an inlet port. This compressed air moves the rotor in a counterclockwise direction. The pressure on air is reduced after it moves the rotor. This air is then released into the atmosphere through the outlet port.

Hydraulic Gear Motor

This kind of motor is used in external gear pumps and is also known as external gear motor. The motor is fitted with two gears which rotate against each other. One of the gears is powered by an inflow of fluid which enters through an inlet; the power from the first gear is transferred into the second one and both gears are set into motion. The fluid moves inside the casing, travels along the periphery of gears and finally reaches the other side (of gears). The fluid is removed from the casing through an outlet. This type of motor is known for its low efficiency.

Applications of Hydraulic Motor

Hydraulic motors are used in different applications including crane drives and winches. The motor is also used in military vehicles, excavators and self-driven cranes. Its applications includes feeder & conveyor drives, roll mills, agitator and mixer drives, drum drives for digesters, shredders for cars, kilns & trommers, trench cutters, drilling rigs, etc.

Hydraulic motors have a wide range of applications and play an important role in day-to-day life. The facts mentioned above should help us understand the working of hydraulic motors and its different types in a better manner.